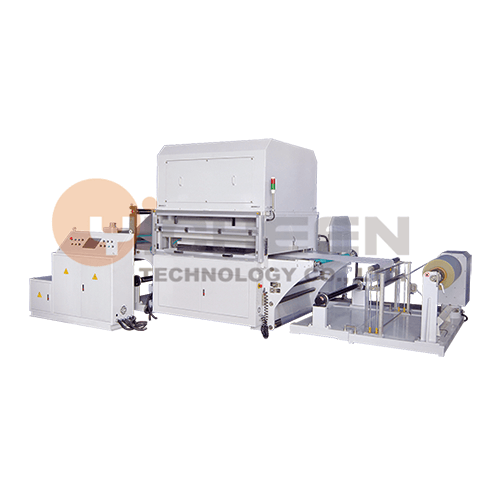

High Precision Hydraulic Type Die Cutting Machine

Categories : Cutting Machines

Application:Plastic films, such as diffuser, reflects sheet, brightness Enhancement Film, PET, PE, PVC, Paper, Self-adhesived label…etc. yicheen Max. cutting square is 1500x1500mm. PLC computer touch-panel screen control system – clear & easy in operation. Equipped with high precision mold high fine adjustment control, Four-columns can be micro-adjusted independently by computer setting parameter, to save time and to raise the production rate. Precision die cut position matching; save time & accurate in die cut mold replacement. Die mold less worn, Long lifetime in use. Also, Optional equipped with knife mold rotative mechanism, it makes the knife mold replaced convenient. Equipped with sticky mechanism, it can effectively clear dust/shavings after cutting. Optional equipped with Static eliminating device and board cleaner. Equipped with safety shelf and safety sensor on each size of machine in order to avoid any dangers while operation. Optional mechanisms: Rewind stacking system, Unwind system (shelf system or shelfless system).

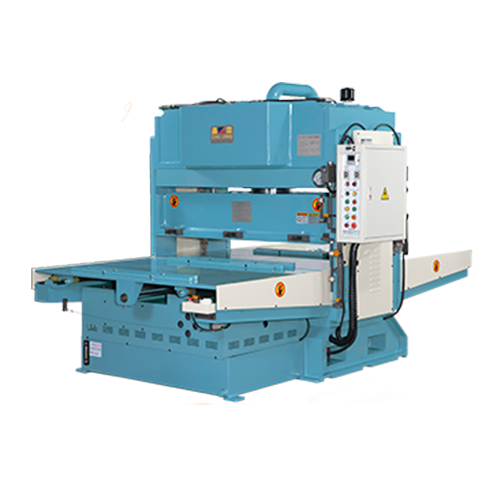

Hydraulic Type Die Cutting Machine With Sliding Table Feeding

Categories : Cutting Machines

Four column of hydraulic cylinder, average cutting force. Microcomputer controller for maximum operation convenience. High speed sliding table feeding, motion is fast and safe. Safety sensor is equipped in front of cutter, (when sensor is touched, the machine automatically stops the action). Application:Special design for die cutting one layer or several layers of such material as rubber sheet, leather, plastic, foam, nylon, paper board and synthetic material. yicheen

High Precision Die Cutting Machine (Full Electrical, One Sheet Feeding)

Categories : Cutting Machines

Application:High precision die cutting machine (Full electrical, one sheet feeding) yicheen

High Precision Die Cutting Machine with CCD auto position system

Categories : Cutting Machines

Application:Optical film, Plastic film, e.g.: ITO, Diffuser, Reflects film, Brightness Enhancement Film (BEF), Soft PCB, Composite material. The material are not cracked while cutting. yicheen

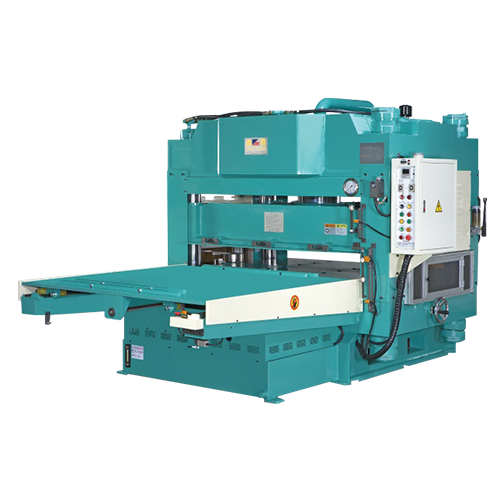

Hydraulic Automatic Feed Die Cutting Machine (Four Column Press)

Categories : Cutting Machines

Application:Suitable for cutting one layer or several layer of such material as rubber sheet (bottom sole, medium sole), EVA, leather, plastic canvas, vacuum foaming products, nylons, carpet, mat, corks, soft tiles, paper boards and synthetic materials. yicheen The improved and upgraded traditional punching machines. Adopt four column of Hydraulic cylinder, average cutting force, high efficiency to raise the productivity. The upper die install by Magnetic platen, it is very convenient to change die. Microcomputer controller with touch sensing screen for maximum operation convenience and accuracy. Also, optional equipped with LCD screen computer control system is available, which it can memory operation program, provide the most convenient in operation and accurate cutting operation. Lubricated system design on Main shaft to avoid machine parts damage in movement and enhance machine lifetime. The Safety device (opening safe net for emergency stop motion) ensures the operator safety. Options: Air shaft unwind device, Air shaft rewind device

HIGH PRECISION HYDRAULIC CUTTING PRESS CSS-607

Categories : Foaming Machinery

The Structure Of Press Body Is Made By Special Steel Shaped Materials That Features Pressure-Resistant Function To Maintain A Permanent Plane, With Its Integrated Shaping Of Punch And Slide To Fully Shows A High Resistance Of Wear And Tear, Excellent Strength And Stable Pressing That Would Help Prolong The Service Life Of The Mold. The Cutting Tool Can Be Used With Laser Cutter For Either Pressing Or Die Pressing, Thus Making Product No Burrs And Enabling Clear Angles. The Blowing Device Can Be Worked Further With Mechanical Action, One Punch And One Blowing Subsequently To Absorb Automatically The Well-Cut Finished-Goods That Makes An Easy Access And Safe To Take Feeds, Along With An Installation Of The Almighty Grooved Base Plate, The Mold Locking Is Convenient And Rapid. With A Device Of Fixed-Point Type Pedal Switch, It Shows Up A Mature Technologic Design For Industrial Use. With Its Semi-Automatic Knife Mold Design, It Enables Operators An Easy And Safe Operation.

Precision Four-Column Plan Hydraulic Cutting Machine-CSS-202B

Categories : Foaming Machinery

●The body of the machine is made of special steel and has gone through rigorous processing that shows a ram pressure-resistant function and precision. ●Up and down stroke applies steel pole as the rail that brings out an effect of high precision and shaking-resistant characteristic. ●A design of Two-pod oil cylinder shows the stable force and large torsion.

High-accuracy Multi-Function Hydraulic Cutting Machine - CSS-603M

Categories : Cutting Machines

The machine body has been machined for several finishing processes in creating low-profile variable high-rigid machine body.

Precision High Speed Hydraulic Automation Cutters-CSS-202

Categories : Foaming Machinery

● The machine adopts two-hand button, safe operation, fast, smooth, strong pressure, no noise, no vibration power, upstairs, downstairs plant can be used, low failure rate, improve production efficiency. ● Die automatic setting: Stroke is simple, fast and accurate, extending the life of knives and knives. ● automatic lubrication system: The use of mechanical parts can be automatically refueling, to ensure that mechanical damage, permanent security precision. ● Can be arbitrarily adjusted to determine the single layer. ● This machine is equipped with brake device to ensure the safety of personnel. ● special models can be customized.

Precision Hydraulic Four Column Type Automatic Feeding Cutter - CSS-806A

Categories : Cutting Machines

Precision Hydraulic Four Column Type Automatic Feeding Cutter

Precision Hydraulic Double-Sided Auto Feed Cutter CSS-806

Categories : Foaming Machinery

Both double-side and single-side operation, time and manpower saving, one machine for two purposes to give excellent effect of production. Double-side pressure and touch-type electronic counter watch are separatively deviced, so different sizes of product can be adopted. Super precision oil way design, silent for performance, stable location for each action, to increase the service life of parts and tool mold deviced with cutting board rotary table, the consumption of cutting board can de reduced. Body frame adopts high tension steel plate under stress relief process for long application without being deformed.(We welcome any special size from buyer).

PRECISION HYDRAULIC AUTOMATIC DIE-CUTTING MACHINE/4COLUMU TYPE CSS-603

Categories : Cutting Machines

Advanced & durable hydraulic circuit and steady electronic control system circuits adopted in the hydraulic system enable to achieve high operating performance. 4 steel posts design instead of guide-ways for punching movement and equipping linear guide-way for the front & rear feeders. The unit performs precisely, stably, quietly, nimble and powerful. lt'sconvenient even for the use at the upstairs of a factory. Cutting depth can be precisely set up to a tolerance of 0.008 mm. Through the use of the longwearing special designed steel plate to replace conventional cutting board, can prolong lift of cutter and obtain better cutting quality and efficiency Processed item may be full or half cut-off. ltems with adhesive may be used as well Products are free from rough edges. The machine is equipped with a protecting device to ensure safety of people and the machine. Automatic cooling system and full-auto cutting device are available for additionally purchase and fitting. Designed in high-precision construction, this machine can be used to perform full-cut and half-cut fabrication tasks. Up/down punching travel uses four high-rigidity guide poles, with linear rail designed for the feeding mechanism. Two-step pressure control to achieve flexible and lower noise operation. It is suitable for multi-level factory buildings. Automatic cutter adjusting mechanism can perform automatic adjustment according to the desired setting, providing 0.01mm accuracy (0.001mm optional). High-precision german steel plate is used to achieve higher durability and wear free operation. This machine uses advanced and durable hydraulic system and electronic control circuits. The machine is equipped with protection device to ensure the safety of the operator and the machine. (with CE optional)